Installing a 30-inch door? Achieving the perfect rough opening is paramount for a flawless fit, distinguishing between a professional outcome and a source of frustration. Amidst the sea of confusing online advice, this guide offers unparalleled clarity. It provides a comprehensive, step-by-step approach to accurately measure and frame your door opening, ensuring a successful installation. Whether you’re a seasoned professional or a DIY novice, this resource equips you with the essential knowledge to avoid costly errors. From defining the fundamentals of a rough opening to resolving challenges like irregular walls, this guide simplifies the process, helping you sidestep common pitfalls and costly mistakes. Let’s begin!

The Importance of Accurate Rough Openings

Accurate rough openings ensure your door operates smoothly, seals correctly, and lasts longer. A poorly sized opening can lead to:

- Drafts and Energy Loss: Gaps around the door allow air infiltration, increasing energy bills.

- Difficulty Opening/Closing: A tight fit can cause the door to stick or bind.

- Premature Wear: Forced operation can damage the door, frame, and hardware.

- Security Issues: An improperly installed door compromises your home’s security.

Deciphering Door Terminology: Essential Definitions

Before measuring, familiarize yourself with these terms:

-

Rough Opening (RO): The framed opening in the wall before the door frame is installed. It’s intentionally larger than the door to allow for adjustments and shimming.

-

Finished Door Size: The actual dimensions of the door slab itself (e.g., 30 inches wide by 80 inches high).

-

Door Frame (Jamb): The surrounding framework into which the door is fitted, consisting of the head (top), sill (bottom), and side jambs.

-

Stud: Vertical framing members that make up the wall.

-

Header: A horizontal beam above the rough opening that supports the load from the structure above.

-

King Stud: Full-height studs that run from the bottom plate to the top plate on either side of the opening.

-

Jack Stud (Trimmer Stud): Shorter studs that run from the bottom plate to the header, supporting the header and framing the sides of the rough opening.

-

Shims: Thin, tapered pieces of wood used to adjust the door frame within the rough opening, ensuring it’s plumb, level, and square.

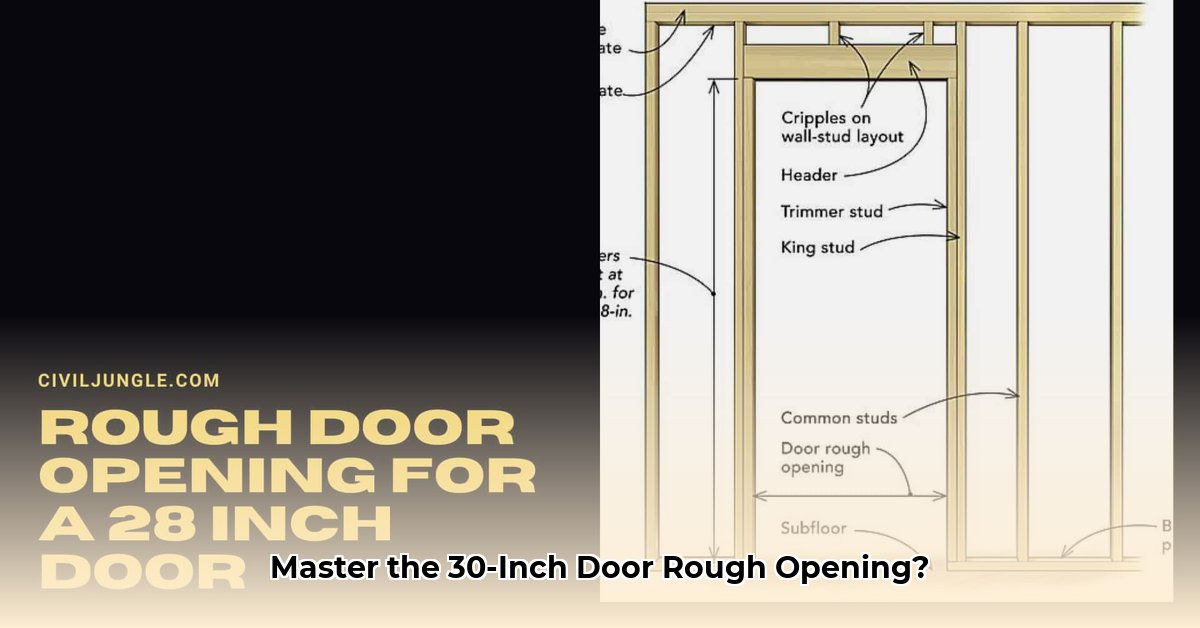

(Include a clearly labeled diagram showing each of these elements in a wall section. This diagram should be visually distinct and easy to understand, using clear callouts and concise labels.)

Step-by-Step Guide: Measuring for a 30-Inch Door Rough Opening

Precision is key to a successful door installation. Follow these steps meticulously:

Step 1: Measure the Door:

Use a tape measure to accurately determine the width and height of the 30-inch door slab. Record these measurements – they’re crucial for subsequent calculations. Double-checking at this stage will prevent future errors.

Step 2: Account for Variables:

Consider these factors, which influence your rough opening measurements:

- Flooring Thickness: Account for the finished flooring (tile, hardwood, carpet) height. Measure from the subfloor to the top of the finished floor to determine the exact thickness. This measurement is added to the door’s height to ensure correct door clearance.

- Wall Construction: Is the wall framed with 2×4 or 2×6 studs? 2×6 walls are thicker, requiring a deeper rough opening. Measure the wall’s thickness to ensure the door frame sits flush.

- Door Type: Solid-core doors are heavier than hollow-core doors. Consider a slightly larger rough opening for solid-core doors to accommodate the extra weight.

- Special Features: Note any sidelites (vertical windows beside the door), transoms (horizontal windows above the door), or astragals (vertical moldings between double doors). These elements require additional space in the rough opening.

- Wall Imperfections: Use a level and square to check the existing wall for plumbness and squareness. Uneven walls require shimming, affecting rough opening dimensions. Document any deviations so that you know what to shim.

Step 3: Calculate the Rough Opening Dimensions:

While adding 2 inches to the width and 2.5 inches to the height is a common rule of thumb, it doesn’t account for all variables. Use this detailed table for a more precise calculation:

| Door Width (inches) | Door Height (inches) | Door Type | Added Width (inches) | Added Height (inches) | Minimum Rough Opening (W x H) | Notes |

|---|---|---|---|---|---|---|

| 30 | 80 | Solid Core | 2.5 | 3 | 32.5″ x 83″ | Provides extra space for easier adjustments and heavier door weight. |

| 30 | 80 | Hollow Core | 2 | 2.5 | 32″ x 82.5″ | Standard allowance for typical hollow core door installation. |

| 30 (per leaf) | 80 | French Doors | 3 per leaf | 3 per leaf | 36″ x 83″ (Total Width) | Each door leaf needs additional space for smooth operation; remember to verify manufacturer’s specifications for double doors. |

| 30 | 84 | Standard | 2.5 | 3 | 32.5″ x 87″ | Adjusts for taller door heights, maintaining standard spacing. |

| 30 | 96 | Tall | 2.5 | 3 | 32.5″ x 99″ | Essential for creating sufficient space above unusually tall doors. |

(This table provides general guidelines. Always consult the door manufacturer’s specifications for precise rough opening requirements.)

Step 4: Verify Measurements: Before cutting any framing members, double and triple-check all measurements. Small errors accumulate and cause significant installation problems.

Essential Tools for Precision Framing

Gather these tools for accurate measurements and framing:

- High-Quality Tape Measure: Essential for precise measurements. Choose one with a wide blade and clear markings.

- Level (48-inch or longer): Use to ensure walls are plumb and headers are level.

- Square: Essential for ensuring corners are square (90 degrees). A speed square or framing square will work.

- Laser Level (Optional): For increased accuracy, especially over longer distances.

- Stud Finder: Locates studs behind drywall for secure attachment of framing members.

- Pencils: For marking measurements on framing lumber.

- Safety Glasses: Protect your eyes from dust and debris.

Framing the Rough Opening: A Concise Guide

Framing the rough opening involves these fundamental steps:

- Calculate and Cut: Based on measurements, cut the header, king studs, jack studs, and cripple studs (short studs above the header if needed).

- Assemble Header: Construct the header, ensuring it’s adequately sized for the load it will bear (consult local building codes for header span requirements).

- Install King Studs: Affix the king studs to the top and bottom plates, ensuring they are plumb.

- Add Jack Studs: Position the jack studs against the king studs, supporting the header.

- Secure Header: Fasten the header to the jack studs and king studs.

- Check for Square and Plumb: Continuously verify the assembly is square and plumb as it is constructed.

(Include a simple diagram or photo illustrating the basic framing steps. This visual should show the placement of the header, king studs, and jack studs.) Always conform to local building codes, ensuring structural integrity and safety.

Troubleshooting Common Issues: Solutions for a Seamless Installation

Address these common problems during door installation:

-

Out-of-Plumb Walls: Use shims to correct for walls that are not perfectly vertical. Place shims behind the door frame at the stud locations to bring the frame into plumb.

-

Incorrect Header Height: If the header is too low, remove and replace it with a properly sized header. Consult a professional if unsure about load-bearing requirements. If the header is too high, add shims or a filler piece to the top of the frame.

-

Door Frame Binding: Check for squareness and plumbness of the rough opening. Use shims to adjust the frame until the door swings freely without binding.

Achieving Success: Final Tips for a Perfect Door Installation

Careful measurement and precise framing are the foundation for a successful door installation. By following these steps and taking your time, you can confidently complete your project. Always consult local building codes, and don’t hesitate to seek professional advice when needed. Share your experiences and insights in the comments to help others embarking on similar projects.

- Modern Backsplash Ideas: A Guide to Todays Kitchen Trends - December 18, 2025

- Ceramic Kitchen Wall Tiles: Style and Protection for Your Walls - December 17, 2025

- Kitchen tiling wall: Elevate your kitchen with stylish wall tiles - December 16, 2025