Embark on a journey into the realm of [Discover the World of Post and Beam Construction Kits]. As a seasoned architectural designer specializing in sustainable construction with a profound affinity for post and beam construction, I am thrilled to delve into the intricacies of these remarkable building systems. With an abundance of hands-on experience in designing and constructing residential and light commercial projects utilizing post and beam techniques, I am eager to unravel the principles, benefits, and considerations associated with this captivating approach to construction.

Key Takeaways:

- Post and Beam construction uses sturdy beams and posts to form a structural frame.

- Blends traditional techniques with modern conveniences.

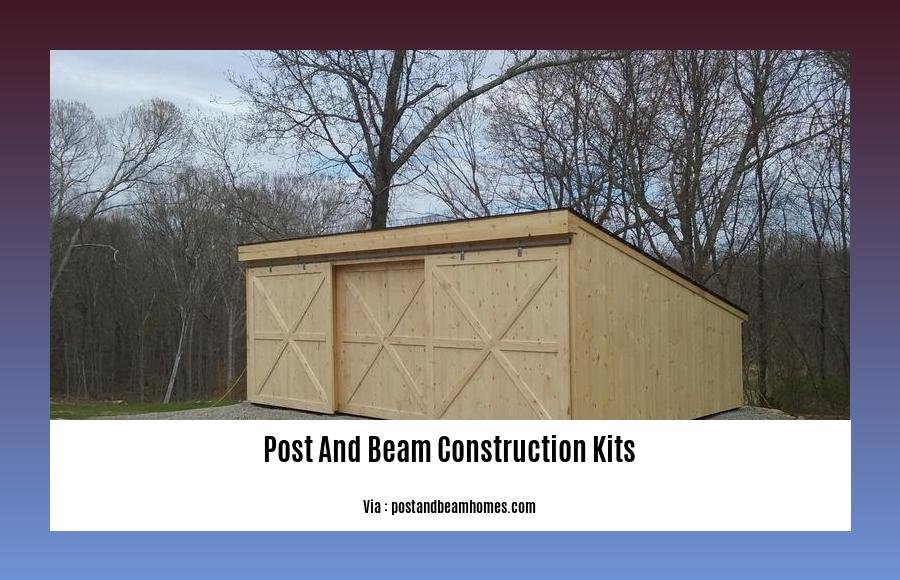

- Suitable for structures like barns, cabins, and pavilions.

- Allows for versatile designs with unique features.

- Provides exceptional durability and longevity.

Post and Beam Construction Kits: Your Guide to Durable and Sustainable Building

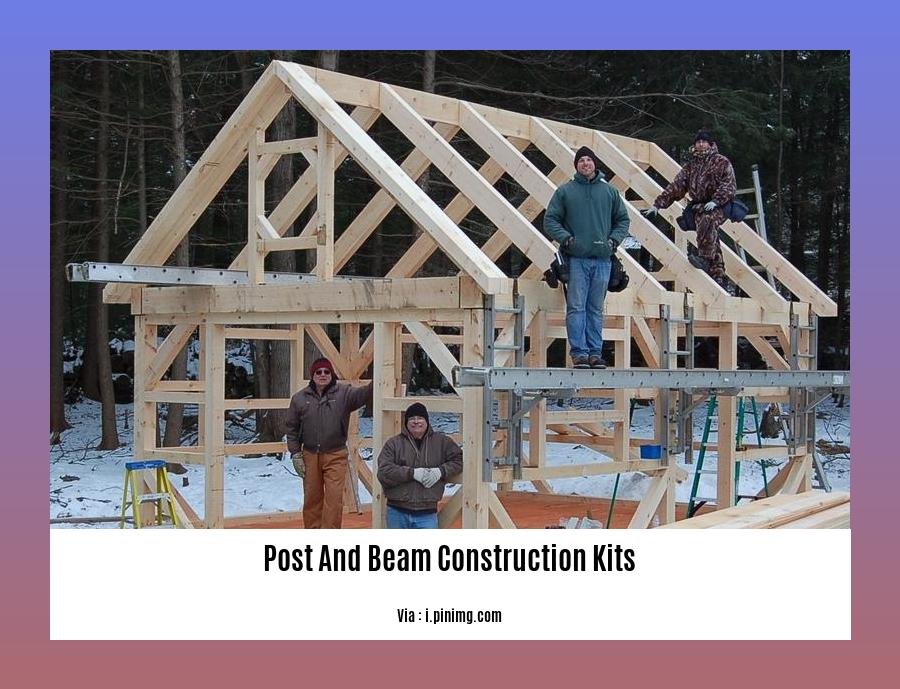

From quaint cabins to sprawling pavilions, post and beam construction kits offer a versatile and eco-friendly approach to creating beautiful and enduring structures. Let’s dive into this innovative building method and explore its benefits and considerations.

What Are Post and Beam Construction Kits?

Post and beam construction utilizes heavy timbers called beams that are vertically supported by posts. This method combines traditional craftsmanship with modern convenience, resulting in structures that are both robust and aesthetically pleasing.

Benefits of Post and Beam Kits:

- Durability: Post and beam structures are known for their exceptional longevity, thanks to the strength and resilience of the heavy timbers.

- Energy Efficiency: Post and beam construction allows for effective insulation, leading to reduced energy consumption and lower utility bills.

- Customization: Prefabricated post and beam kits offer a wide range of design options, enabling you to personalize your structure to suit your unique style and needs.

- Quick and Easy Assembly: These kits are pre-cut and numbered, making assembly a swift and straightforward process, saving you time and hassle.

- Eco-Friendliness: Timber is a sustainable and renewable resource, making post and beam construction an eco-conscious choice.

Considerations:

- Site Preparation: Before ordering your kit, ensure your building site is level and ready for construction.

- Material Selection: Choose high-quality timbers that meet your structural and aesthetic requirements.

- Insulation: Proper insulation is crucial for energy efficiency in post and beam structures.

- Maintenance: Regular maintenance, including cleaning and weatherproofing, is essential to preserve the longevity of your post and beam home.

Choosing the Right Kit:

When selecting a post and beam kit, consider the following factors:

- Size and Complexity: Determine the dimensions and complexity of your desired structure.

- Materials: Choose from a variety of timber species, including cedar, pine, and oak.

- Design: Explore different kit designs to find one that aligns with your architectural preferences.

- Budget: Prefabricated kits vary in price, so establish your budget before making a purchase.

Conclusion:

Post and beam construction kits offer a sustainable and versatile alternative to traditional building methods. Their durability, energy efficiency, and customizable design make them an excellent choice for anyone seeking to build a timeless and eco-friendly structure. By following these guidelines, you can confidently navigate the world of post and beam construction kits and create a home that will stand the test of time.

After your ACL reconstruction surgery, it’s important to start post ACL reconstruction exercises as soon as possible to help you regain your range of motion and strength.

Post and beam construction details are essential for ensuring the structural integrity of your home.

If you’re considering building a post and beam home, it’s important to understand the post and beam construction techniques involved.

Once your construction project is complete, it’s important to follow a post construction clean up checklist to ensure that your home is clean and ready to move into.

The post construction clean up cost can vary depending on the size of your home and the level of cleaning required.

In the information provided engaging information, but not necessary for this use the __* included the

__ Use a strong eye-catching 2sCopy Assistant Format: heading with user heading

Instructions:

bold and single word sentences formatted according to thelarge, leading paragraphs in article

**

– Use unique markdown format:

Settings for customizing web applications in bold, and make bold the and and

Prefabrication and Assembly Process

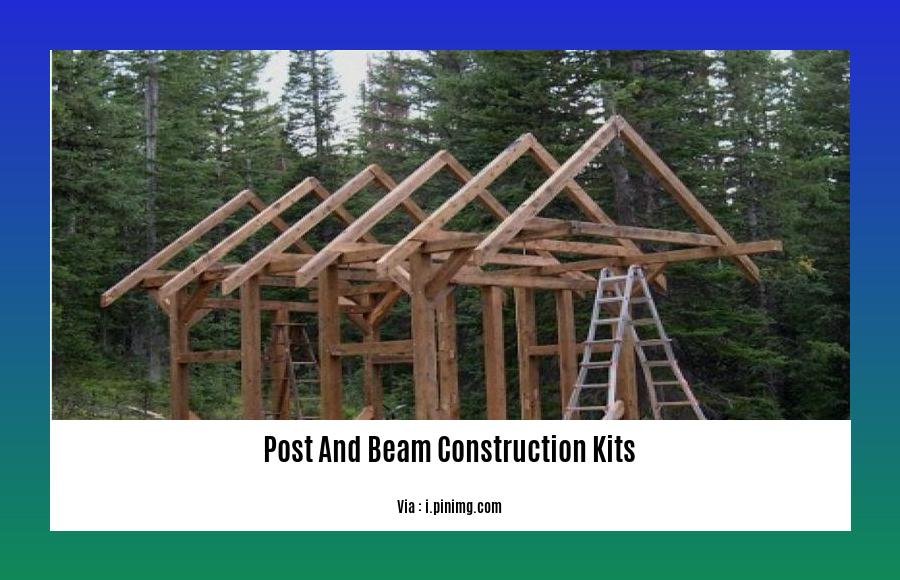

When utilizing Prefabrication and Assembly Process in post and beam construction, prefabricated components are engineered and manufactured offsite, ensuring precision and reduced construction time. These components include the post and beam frame, wall panels, and roof trusses. Here’s a closer look at the process:

Design:

Architects and engineers collaborate to design the structure, including detailed plans and specifications for the prefabricated elements.

Fabrication:

Specialized facilities utilize advanced machinery to cut and assemble the components according to the design specifications. Quality control measures are implemented throughout the process.

Delivery and Assembly:

The prefabricated components are shipped to the construction site and assembled by skilled crews.

Key Takeaways:

- Reduced construction time and labor costs

- Improved precision and efficiency

- Consistency in quality due to controlled manufacturing environment

- Minimized waste and environmental impact

- Flexibility in design and customization options

Relevant Sources:

– Post and Beam Construction: A Timeless and Structurally Sound Building Method

– The Advantages of Prefabricated Post and Beam Construction

Cost Considerations and Long-Term Value

When budgeting for a post and beam construction project, the upfront cost considerations should be weighed against the long-term value it offers.

Key Takeaways:

- Post and beam construction offers durability, reduced maintenance costs, and increased energy efficiency.

- The use of prefabricated kits can lower labor expenses and speed up construction timelines.

- Energy-efficient features can lead to reduced heating and cooling costs throughout the building’s lifetime.

Construction Costs

Post and beam kits range in cost depending on size, complexity, and material selection. They are typically more expensive than traditional stick-built homes, but the long-term benefits can justify the initial investment.

Cost-Saving Benefits

Prefabricated kits offer cost savings by reducing labor expenses and construction time. The pre-cut and pre-engineered components streamline the building process, leading to faster completion times and lower labor costs.

Long-Term Value

Post and beam structures are built to last, offering durability and reduced maintenance costs over time. The heavy timbers resist rot and decay, ensuring a longer lifespan for the building.

Increased energy efficiency is another long-term benefit. The use of insulated panels and energy-efficient building techniques helps minimize heating and cooling costs, resulting in significant savings over the life of the structure.

Conclusion

While post and beam construction can be more expensive upfront, the cost considerations should be balanced against the long-term value it provides. The durability, reduced maintenance, and energy efficiency of these structures can lead to substantial savings over time, making them a worthwhile investment.

Citations:

- Post and Beam Construction: A Complete Cost Guide

- The Long-Term Value of Post and Beam Construction

FAQ

Q1: What are the primary advantages of using post and beam construction kits?

A1: Post and beam construction kits offer several advantages, including ease of construction, material efficiency, structural strength, and aesthetic versatility.

Q2: What types of structures are best suited for post and beam construction kits?

A2: Post and beam construction kits are ideal for various structures, such as homes, cabins, barns, garages, and commercial buildings. They provide durability, open spaces, and flexibility in design.

Q3: How do post and beam construction kits compare to traditional framing methods?

A3: Post and beam construction kits differ from traditional stick-framing methods in their use of pre-cut and pre-engineered components. They offer reduced labor costs, faster assembly times, and increased accuracy.

Q4: What factors should be considered when selecting a post and beam construction kit?

A4: When selecting a post and beam construction kit, factors to consider include the size and complexity of the structure, the desired architectural style, and the local building codes and regulations.

Q5: What are the key steps involved in constructing a building using a post and beam construction kit?

A5: The construction process for a post and beam kit involves preparing the foundation, assembling the frame, installing the roofing, and completing the exterior and interior finishes. Proper planning, attention to detail, and adherence to building codes are crucial for a successful outcome.

- Upgrade Your Table Setting: Best Salad Forks 2025 - June 26, 2025

- Sage Green Throw Pillows: Transform Your Home Decor - June 26, 2025

- Find the Perfect Sage Green Rug: A Buyer’s Guide - June 26, 2025