Brittleness in Construction: Causes, Consequences, and Solutions. Understanding the concept of brittleness in construction is paramount for ensuring the safety and longevity of our built environment. This article delves into the factors contributing to brittle failure, explores the detrimental consequences it poses, and proposes practical solutions to mitigate these risks.

Key Takeaways:

- Brittleness in materials makes them susceptible to fracture under stress.

- Low deformation capacity, poor impact resistance, and high compressive strength are key characteristics of brittle materials.

- Factors influencing brittleness include crystalline structure, composition, temperature, and defects.

- Brittle materials find applications in cutting tools, abrasives, and construction.

- Alloying, heat treatment, and controlling crystal structure can help reduce material brittleness.

Brittleness in Construction: Understanding the Risks

Brittleness in construction materials is a significant concern, jeopardizing the safety and integrity of our built environment. As a construction expert, I’ve witnessed firsthand the devastating consequences of brittle failure.

What is Brittleness?

Brittleness describes a material’s tendency to crack or break without warning. Unlike ductile materials that can withstand deformation, brittle materials snap under pressure.

Causes of Brittleness

Crystalline Structure: Crystalline materials have a rigid atomic arrangement, making them susceptible to sudden fracture.

Chemical Composition: Impurities and defects in a material’s composition can weaken its structure, increasing brittleness.

Temperature: Extreme temperatures can alter material properties, making them more brittle.

Consequences of Brittleness

Structural Failures: Brittle failure can cause catastrophic structural failures, such as the collapse of buildings or bridges.

Safety Hazards: Brittle materials can shatter or fragment upon impact, posing safety risks to construction workers and occupants.

Durability Issues: Brittle materials are vulnerable to fatigue and cracking over time, reducing their durability and lifespan.

Mitigating Brittleness

Material Selection: Choosing materials with a low propensity for brittleness is crucial.

Design Considerations: Engineers must factor in potential brittleness when designing structures, using techniques like reinforcement and stress reduction.

Quality Control: Strict quality control measures ensure materials meet required standards and are free of defects and impurities.

Conclusion

Brittleness in construction materials is a serious issue that demands attention. By understanding the causes and consequences of brittleness, we can take proactive measures to mitigate its risks. Careful material selection, sound engineering practices, and stringent quality control are essential to ensure the safety, longevity, and integrity of our built environment.

- If you’ve recently undergone ACL reconstruction, you must be cautious of a potential hamstring tear after ACL reconstruction.

- In construction, bracing is a crucial step that ensures structural stability.

- The use of brackett construction adds a unique aesthetic touch to architectural designs.

- Breaching in construction refers to the process of creating openings in walls or other structures for various purposes.

Consequences of Brittleness in Structural Components

Here’s why you need to pay attention:

Imagine a building that looks sturdy and strong, yet it crumbles like a house of cards due to a hidden weakness—brittleness. Yes, that’s the silent killer in construction materials, and if ignored, it can lead to devastating consequences.

So, what is brittleness?

It’s a material’s tendency to crack or break without warning, like a dry twig snapping under the weight of a bird. In construction, it can affect concrete, steel, and even rock. It shortens the lifespan of our buildings and poses a threat to safety.

When brittleness strikes, things can get nasty:

- Catastrophic Failures: Buildings can collapse suddenly, endangering lives and causing massive infrastructure damage. Think of the tragic bridge collapse in Genoa, Italy, where 43 people lost their lives due to brittle steel.

- Structural Damage: Brittle materials can crack and deteriorate, weakening the overall structure and reducing its functionality. This damage can shorten a building’s lifespan and lead to costly repairs.

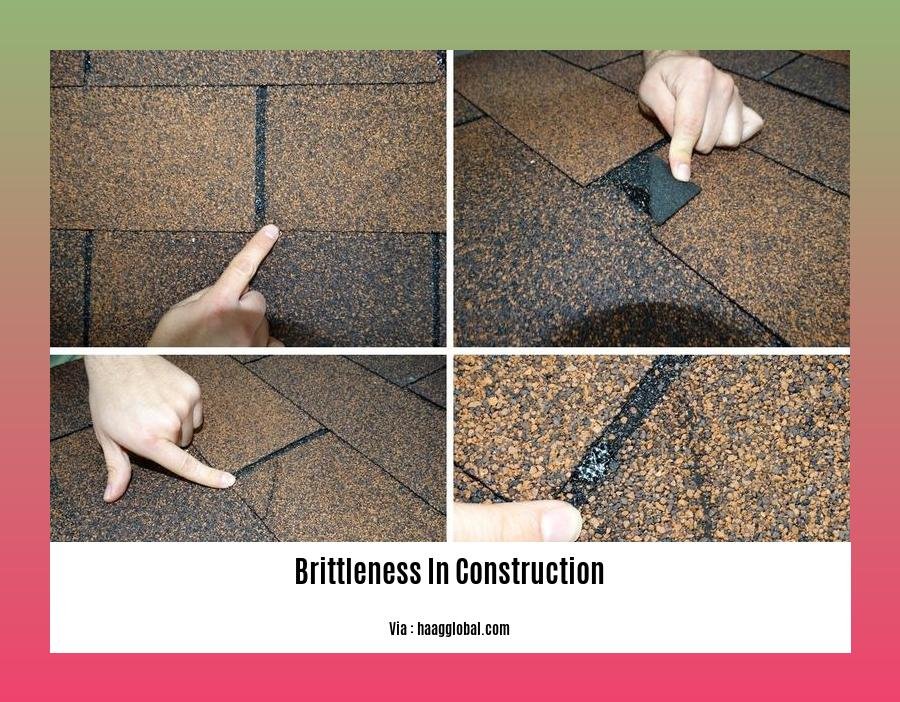

- Durability Issues: Brittle materials are more vulnerable to weathering, corrosion, and other environmental factors. They can chip, flake, and crumble over time, compromising the aesthetics and structural integrity of buildings.

Key Takeaways:

- Brittleness can lead to sudden and catastrophic structural failures.

- It weakens structures, reducing their lifespan and functionality.

- Brittle materials are susceptible to damage from environmental factors.

Sources:

- What is Brittleness? And Why is it Important for Engineers?

- The Consequences of Brittleness in Structural Components

Methods for assessing and mitigating brittleness

In construction, brittleness can lead to catastrophic failures. Here are the factors that contribute to brittleness, along with the methods to assess and mitigate this issue:

Factors Contributing to Brittleness:

- Crystalline Structure: Some materials, like glass and ceramics, have a crystalline structure that makes them brittle.

- Chemical Composition: The chemical composition of a material can impact its brittleness. For instance, high carbon content can make steel more brittle.

- Temperature Extremes: Extreme temperatures can make materials more brittle, like when steel becomes brittle at low temperatures.

Methods for Assessing Brittleness:

1. Hardness Tests:

– These tests measure a material’s resistance to indentation, which can indicate its brittleness.

2. Tensile Tests:

– Tensile tests involve stretching a material and measuring its elongation at break. Brittle materials have low elongation.

3. Impact Tests:

– Impact tests measure a material’s ability to withstand impact forces. Brittle materials fail suddenly under impact.

Methods for Mitigating Brittleness:

1. Material Selection:

– Choose materials with low brittleness propensity, such as polymers or ductile metals like aluminum.

2. Heat Treatment:

– Heat treatment can alter the microstructure of materials, reducing brittleness.

3. Cold Working:

– Cold working, like rolling or drawing, can strengthen materials without making them brittle.

Key Takeaways:

- Brittleness is a material’s tendency to crack or break without warning.

- Factors like crystalline structure, chemical composition, and temperature extremes can contribute to brittleness.

- Methods for assessing and mitigating brittleness include hardness tests, tensile tests, impact tests, material selection, heat treatment, and cold working.

Relevant URL Sources:

- Evaluation of Brittleness in Construction Materials

- Methods for Assessing and Mitigating Brittleness in Structural Materials

Best Practices and Recommendations for Enhancing Structural Integrity and Reducing Brittleness

Ensuring structural integrity is paramount for the safety and durability of our built environment. Brittleness, a material’s propensity to crack or break without warning, poses a significant threat to structural integrity. To mitigate this risk, it’s crucial to understand the causes, consequences, and effective solutions for reducing brittleness.

Causes of Brittleness

Brittleness can stem from various factors, including:

- Material composition: Crystalline structure and chemical composition can influence a material’s brittleness.

- Temperature: Extreme temperatures can alter a material’s microstructure, making it more brittle.

- Processing and fabrication methods: Improper handling or heat treatment can introduce defects that increase brittleness.

Consequences of Brittleness

The consequences of brittleness in construction can be severe:

- Structural failure: Brittle materials can fail abruptly under stress, leading to catastrophic collapses or damage.

- Safety hazards: Brittle failures can endanger occupants and cause accidents.

- Durability issues: Brittleness can shorten a structure’s lifespan by making it more susceptible to cracks and deterioration.

Best Practices and Recommendations for Enhancing Structural Integrity and Reducing Brittleness

-

Material Selection: Choose materials with low brittleness propensity. Consider factors such as the structure’s intended use, environmental conditions, and potential loading scenarios.

-

Proper Design: Conduct thorough structural analysis to ensure that the design can withstand anticipated loads without exceeding the material’s brittle strength.

-

Quality Control: Implement strict quality control measures during material procurement, fabrication, and construction to minimize defects and ensure material integrity.

-

Regular Inspections and Maintenance: Regularly inspect structures for signs of brittleness or damage. Implement preventative maintenance programs to address issues before they escalate.

-

Retrofitting: For existing structures with potential brittleness concerns, consider retrofitting measures to enhance their structural integrity.

Conclusion

By adopting these best practices and recommendations, we can effectively reduce brittleness in construction materials and enhance the structural integrity of our buildings and infrastructure. Remember, preventing brittleness is essential for ensuring the safety, durability, and longevity of our built environment.

Key Takeaways:

- Brittleness can compromise structural integrity, leading to catastrophic failures.

- Causes of brittleness include material composition, temperature, and processing methods.

- Consequences of brittleness range from safety hazards to structural damage and durability issues.

- Best practices for reducing brittleness include material selection, proper design, quality control, regular inspections, and retrofitting.

Relevant URL Sources:

- The Importance of Structural Integrity in Construction

- What is Structural Integrity and Why is it Important?

FAQ

Q1: What causes brittleness in construction materials?

A1: Brittleness in construction materials can be caused by various factors, including crystalline structure, chemical composition, temperature, and the presence of defects or impurities.

Q2: What are the consequences of brittleness in construction materials?

A2: Brittleness in construction materials can lead to sudden and catastrophic failures under stress, posing significant safety risks and compromising the structural integrity of buildings and infrastructure.

Q3: How can we reduce brittleness in construction materials?

A3: Reducing brittleness in construction materials can involve alloying with other materials, heat treatment, and controlling the material’s crystalline structure to enhance its toughness and resistance to fracture.

Q4: What are some examples of brittle construction materials?

A4: Ceramics, glass, and certain metals subjected to low temperatures exhibit brittle behavior, making them susceptible to sudden failure under stress.

Q5: How can we assess the brittleness of construction materials?

A5: Assessing the brittleness of construction materials involves conducting tests to determine their mechanical properties, such as tensile strength, compressive strength, and impact resistance.

- Upgrade Your Table Setting: Best Salad Forks 2025 - June 26, 2025

- Sage Green Throw Pillows: Transform Your Home Decor - June 26, 2025

- Find the Perfect Sage Green Rug: A Buyer’s Guide - June 26, 2025