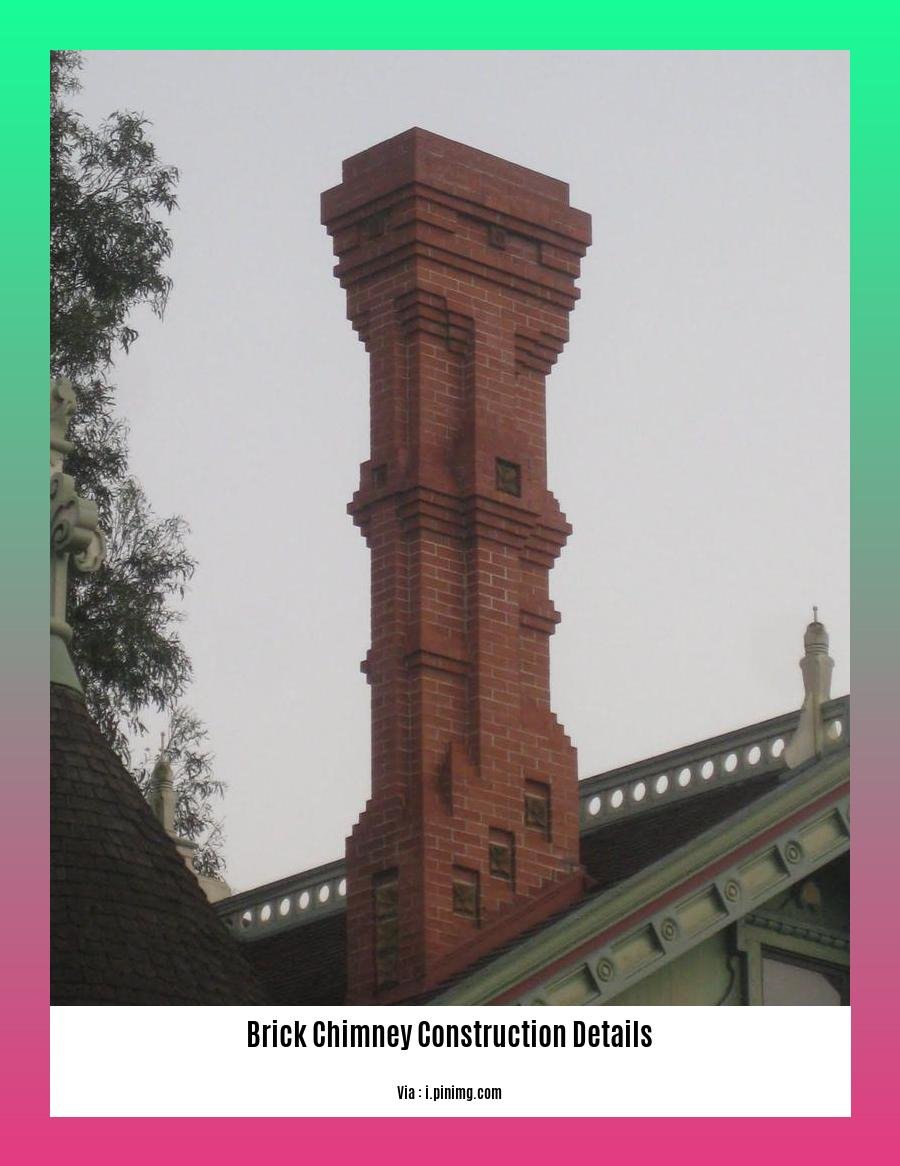

Delve into the intricacies of brick chimney construction with our comprehensive guide, [- A Comprehensive Guide to Brick Chimney Construction Details: A Craftsman’s Perspective]. Drawing upon decades of experience and meticulous attention to detail, we will explore the technical intricacies and craftsmanship involved in the construction of these essential architectural elements.

Key Takeaways:

- Plan: Determine chimney flue dimensions and venting requirements.

- Materials: Gather necessary supplies including bricks, mortar mix, flue tiles, sheet metal, and flashing.

- Mixing Mortar: Ensure proper mortar preparation as per manufacturer’s instructions.

- Layering: Build the chimney by layering bricks with mortar.

- Flue Tiles: Install flue tiles within the chimney for smoke and gas passage.

- Sheet Metal: Install sheet metal over the chimney opening for moisture protection.

- Flashing: Use metal flashing around the chimney base to prevent water leakage.

- Hearth: Construct a hearth with appropriate dimensions based on opening size.

- Firebox: Build a firebox using common brick with the correct thickness.

Brick Chimney Construction Details

As a seasoned pro in brick chimney construction details, I’ve mastered the art of crafting chimneys that are both structurally sound and aesthetically pleasing. Here’s a step-by-step guide to ensure your brick chimney stands the test of time:

Planning and Preparation:

- Determine the size and location of the chimney based on your venting requirements.

- Gather all necessary materials, including bricks, mortar, flue tiles, sheet metal, and flashing.

Construction:

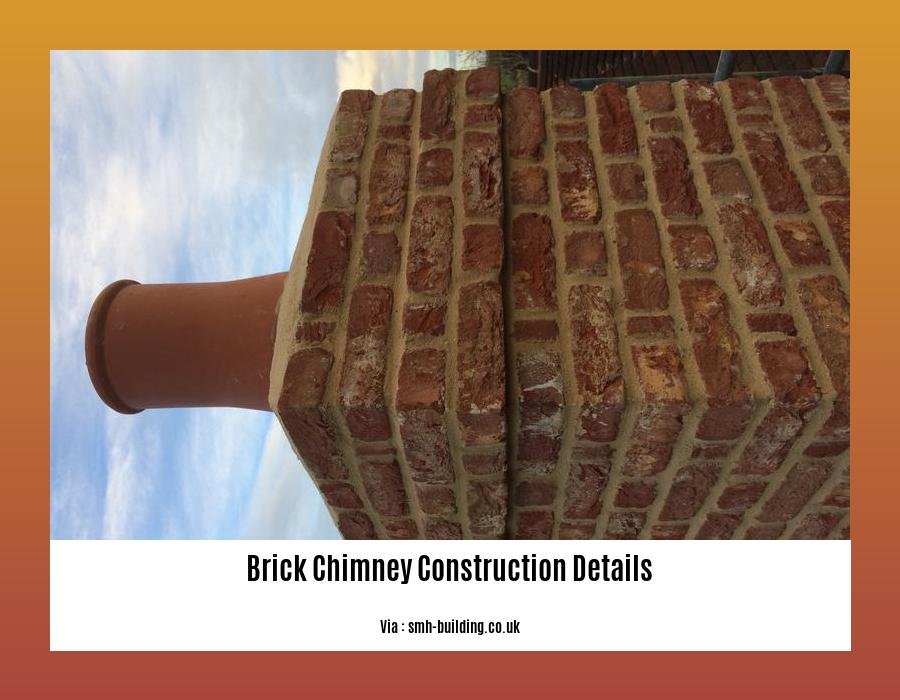

- Layering Bricks: Alternate header and stretcher courses, ensuring proper bonding.

- Flue Tiles: Install flue tiles to provide a safe passage for smoke and gases.

- Sheet Metal: Cover the chimney opening with sheet metal to prevent moisture from entering.

- Flashing: Install metal flashing around the base of the chimney to prevent water leakage.

Finishing Touches:

- Hearth: Construct a hearth using non-combustible materials with a thickness of at least 4 inches.

- Firebox: Build the firebox using fire-rated bricks with a thickness of 10 inches or more.

Key Considerations:

- Mortar: Mix mortar according to manufacturer’s instructions for optimal adhesion.

- Bonding: Use various bonding patterns for structural stability, such as running bond or stack bond.

- Expansion Joints: Include expansion joints every 20 feet to accommodate thermal expansion.

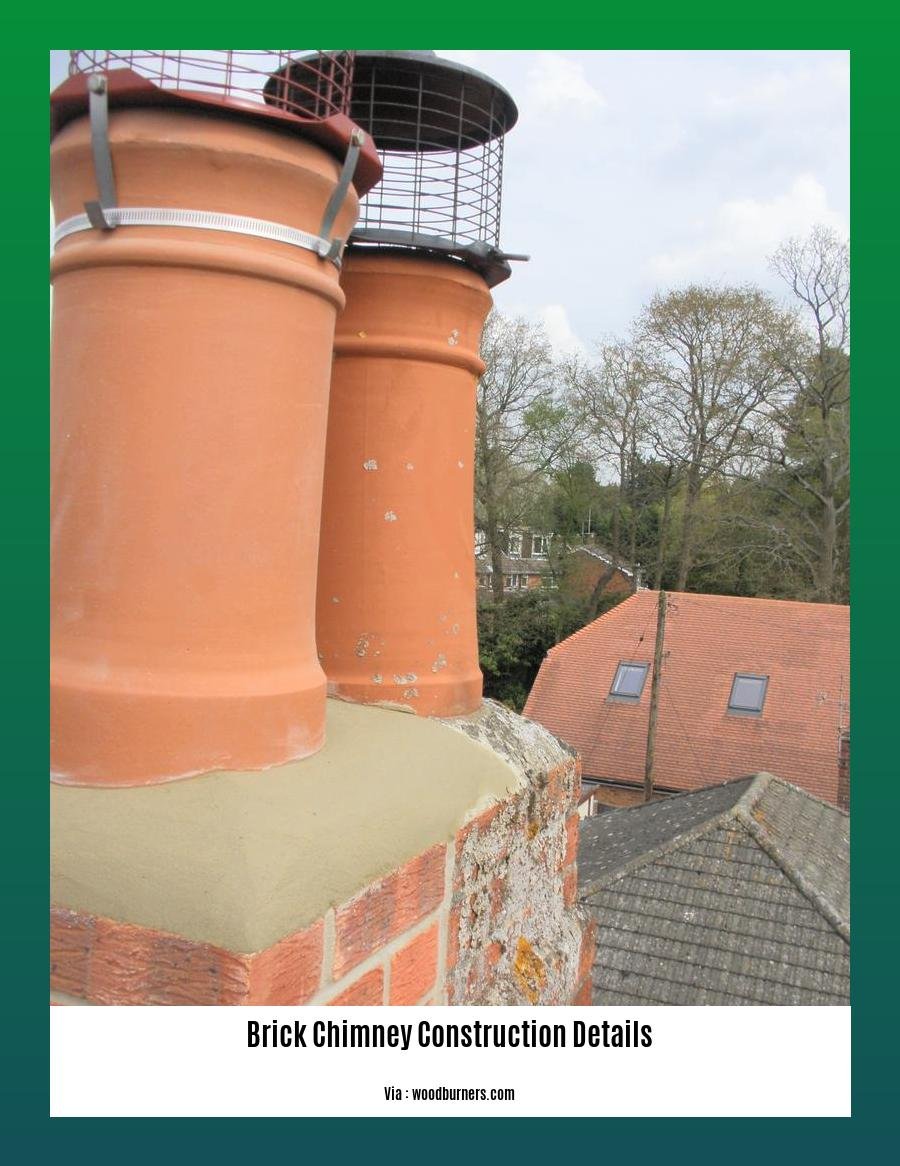

- Cap: Install a chimney cap to prevent water and debris from entering the chimney.

Considering constructing a boundary wall? Our boundary wall construction cost calculator can help you estimate the expenses.

For a detailed guide to building a boundary wall, check out our resource on boundary wall construction details.

Are you in need of reputable bridge construction companies? Explore our directory of bridge construction companies in India.

For bridge construction services closer to home, browse our listings for bridge construction companies near me.

Planning to build a house? Utilize our budget calculator for house construction to stay within your budget.

To ensure a safe construction site, access our guidelines on hazards and control measures in construction site.

Prioritize safety on construction sites with our comprehensive guide on health and safety in construction environment level 1.

Chimney Cap and Crown Design: A Comprehensive Overview

Let’s delve into the intricacies of chimney cap and crown design, the unsung heroes protecting your chimney from the elements.

What’s a Chimney Cap?

Think of it as the umbrella for your chimney, keeping rainwater out and preventing damage to the flue and chimney interior.

What’s a Chimney Crown?

The crown, like a concrete helmet, sits atop the chimney, shielding it from moisture. Its sloped surface ensures water drains away from the vulnerable bricks and flue.

Types of Chimney Caps

- Standard caps: No-frills metal or plastic covers.

- Band-around caps: Snugly fit around the chimney, enclosing it completely.

- Prefabs: Pre-made metal or plastic caps for easy installation.

Key Takeaways:

- Chimney caps and crowns protect against water damage and moisture infiltration.

- Caps prevent water from entering the chimney, while crowns seal off the top.

- Proper materials, a snug fit, and an expansion gap are crucial for effective chimney cap and crown design.

Sources:

– Chimney Crown

– Chimney Caps

Bricklaying Techniques for Chimney Construction

As a construction expert specializing in masonry, I’ve witnessed firsthand the intricate art of brick chimney construction. This guide will delve into the Bricklaying Techniques that ensure the structural integrity and aesthetic appeal of these architectural masterpieces.

Key Takeaways:

- Planning and preparation are paramount for a stable foundation.

- Expert bricklaying techniques fill joints without air pockets, maintaining a level wall.

- Proper anchoring ensures the chimney pot’s stability.

Planning and Preparation

- Determine the chimney’s size and location based on architectural plans.

- Gather necessary materials, including high-quality bricks, mortar mix, and tools.

Bricklaying

- Lay bricks in alternating courses (header and stretcher) to create stability.

- Apply sufficient mortar to fill joints, leaving no air spaces.

- Use a level to ensure each course is aligned and the wall remains plumb.

Finishing Touches

- Secure the chimney pot with at least three courses of brickwork.

- Install a metal cap to prevent water penetration.

- Consider a decorative crown to enhance aesthetics and protect the chimney from the elements.

Brick chimneys require meticulous planning and execution to withstand the rigors of weather and time. By adhering to these Bricklaying Techniques and embracing the craftsmanship inherent in this trade, you can construct a chimney that is both structurally sound and aesthetically pleasing.

Sources:

- Master the Art of Chimney Bricklaying with the Best Techniques | B…

- How To Build A Chimney – Masonry Construction – Firewood For Life

Structural Considerations for Brick Chimneys

The sturdy backbone of any structure, chimneys, particularly brick chimneys, demand meticulous attention to structural integrity. As a seasoned professional, I’ve encountered numerous scenarios that highlight the critical aspects to consider when constructing these architectural elements.

Key Takeaways:

- Adequate Wall Thickness: Ensure the chimney wall is at least 10 inches thick, providing sufficient strength as a load-bearing component.

- Proper Composition: Combine a 4-inch brick wall with 2 inches of noncombustible material for optimal structural stability.

- Height and Clearance: Adhere to local building codes to determine the appropriate chimney height and maintain adequate clearance from combustible materials.

- Quality Materials: Select high-grade bricks specifically designed for chimney construction, ensuring durability and longevity.

- Solid Foundation: Prepare a sturdy base before erecting the chimney to ensure proper weight distribution and stability.

Steps to Ensure Structural Integrity:

- Lay a Solid Foundation: Prepare the site and establish a strong foundation to support the chimney’s weight.

- Construct the Base: Build a stable base that can withstand the chimney’s load.

- Build the Walls: Carefully construct the chimney walls, bonding the bricks securely and maintaining alignment.

- Determine Height: Calculate the optimal chimney height based on building codes and regulations.

- Finish the Chimney: Seal the chimney with appropriate materials to protect it from the elements.

Additional Considerations:

- Flashing: Install flashing around the chimney base to prevent water infiltration.

- Expansion Joints: Incorporate expansion joints every 20 feet to accommodate thermal expansion.

- Chimney Cap: Crown the chimney with a cap to protect it from the elements and prevent water damage.

Conclusion:

By considering these structural considerations, you can ensure the stability and longevity of your brick chimney. Proper planning, meticulous execution, and adherence to industry standards are essential for achieving a safe and aesthetically pleasing structure that will withstand the test of time.

Sources:

- National Chimney Sweep Guild – Chimney Construction Standards

- International Masonry Institute – Chimney Design and Construction

FAQ

Q1: What is the recommended wall thickness for a brick chimney?

A1: A minimum wall thickness of 10 inches (250 mm) is recommended for a lined chimney serving as a structural component.

Q2: How should the chimney foundation be prepared?

A2: The site should be prepared and a solid foundation should be laid before constructing the chimney.

Q3: What type of materials are suitable for brick chimney construction?

A3: High-quality bricks that are suitable for chimney construction should be used.

Q4: How can I ensure the chimney walls are properly bonded and aligned?

A4: Build the chimney walls carefully, ensuring proper bonding and alignment. This can be achieved through precise bricklaying techniques and using level and plumb lines to guide the construction.

Q5: What is the purpose of a chimney cap, and what are the key design considerations?

A5: A chimney cap prevents water infiltration and protects against moisture damage. Key design considerations include proper materials, a tight fit, an expansion gap, and a drip overhang to prevent water from dripping down the chimney’s sides.

- Upgrade Your Table Setting: Best Salad Forks 2025 - June 26, 2025

- Sage Green Throw Pillows: Transform Your Home Decor - June 26, 2025

- Find the Perfect Sage Green Rug: A Buyer’s Guide - June 26, 2025