Journey into the realm of asphalt road construction machines, the powerful workhorses that shape our transportation networks. From the intricate mechanisms of asphalt pavers to the relentless force of rollers, discover the world of these specialized machines and the techniques employed to create smooth, durable asphalt roads. In this comprehensive overview [1. Asphalt Road Construction Machines: A Comprehensive Overview of Equipment and Techniques], we delve into the intricacies of these machines, exploring their capabilities, applications, and the impact they have on project efficiency and asphalt quality.

Key Takeaways:

- Asphalt Plant: A facility that produces asphalt for road construction by mixing aggregate, bitumen, and other materials.

- Truck Crane: A truck-mounted crane with a telescopic boom, commonly used for lifting heavy objects in road construction.

Asphalt Road Construction Machines: Equipment and Techniques

In the realm of road construction, asphalt road construction machines play a pivotal role in shaping our transportation infrastructure. From massive asphalt plants producing tons of asphalt per hour to versatile truck cranes lifting heavy objects with precision, these machines are the backbone of modern road construction.

In this comprehensive overview, we’ll delve into the intricacies of asphalt road construction machines, exploring their functions, applications, and the techniques employed to ensure efficient and high-quality road construction.

1. Asphalt Plant: The Heart of Asphalt Production

At the heart of asphalt road construction lies the asphalt plant, a sophisticated facility designed to produce the essential material—asphalt concrete. This complex mixture of aggregate, bitumen, and other additives is meticulously crafted within the plant, with different sizes catering to projects of varying scales. Larger plants can produce up to 3000 tons of asphalt per hour, making them indispensable for large-scale road construction projects.

2. Truck Crane: A Versatile Lifting Solution

The truck crane, a mainstay in the road construction industry, is a versatile lifting machine mounted on a truck chassis. Its telescopic boom extends and retracts, enabling it to reach various heights and positions. Truck cranes are commonly employed for lifting heavy objects such as concrete beams and steel girders, making them invaluable for bridge construction and other complex projects. Their mobility allows for easy movement between sites, enhancing project efficiency.

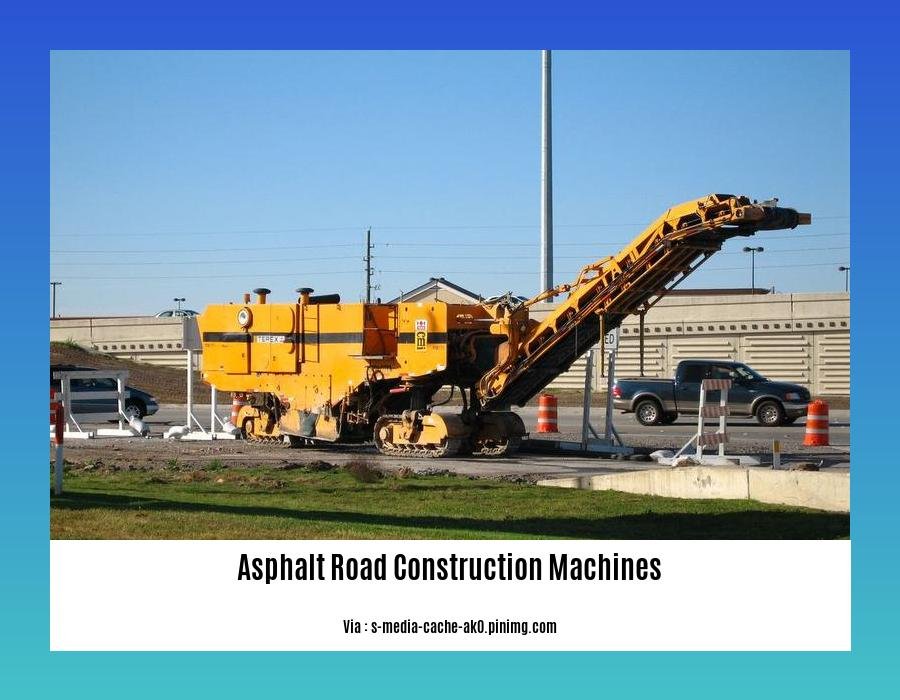

3. Milling Machine: Resurfacing and Recycling

When it comes to road resurfacing or recycling, the milling machine takes center stage. This specialized machine grinds and pulverizes the existing asphalt pavement, creating a uniform surface for new asphalt layers. By recycling the old asphalt material, the milling machine reduces waste and promotes sustainable construction practices. It also enhances the bond between the old and new asphalt layers, ensuring a longer-lasting and smoother road surface.

4. Asphalt Paver: Laying the Foundation

The asphalt paver, a crucial machine in the road construction process, precisely lays the asphalt mixture onto the prepared surface. Its adjustable screed ensures an even distribution and compaction of the asphalt, creating a smooth and level foundation. Sophisticated pavers can handle a variety of asphalt mixtures and thicknesses, catering to specific project requirements.

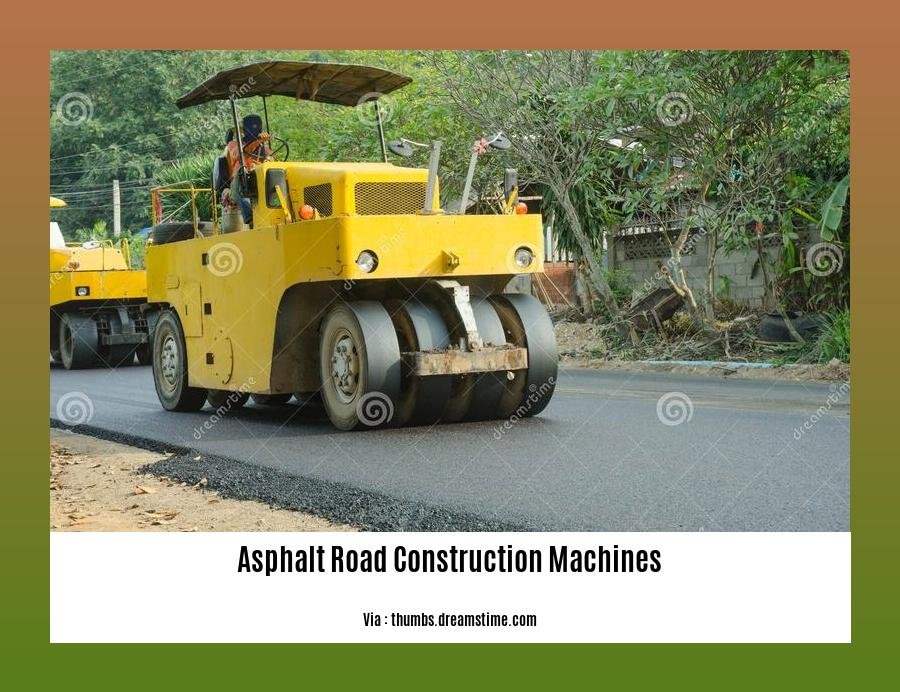

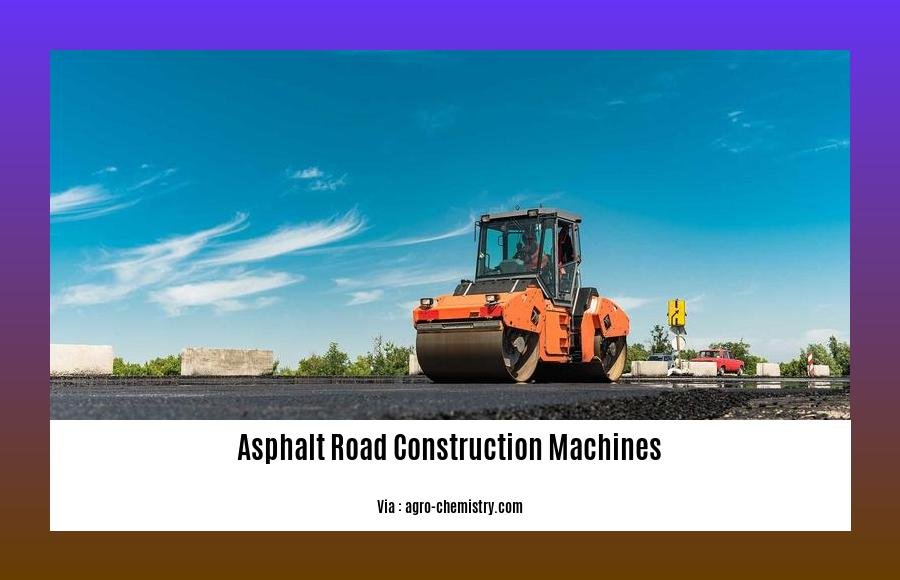

5. Asphalt Roller: Compacting for Strength

Once the asphalt paver has laid the asphalt mixture, the asphalt roller steps in to compact and smoothen the surface. This compaction process enhances the asphalt’s density, increasing its strength and durability. Different types of rollers, including static, vibratory, and pneumatic, are used depending on the project’s specific needs. Proper compaction ensures the longevity and performance of the asphalt pavement.

6. Safety and Maintenance: Cornerstones of Successful Construction

Safety and maintenance are paramount in asphalt road construction. Regular maintenance of asphalt road construction machines ensures their optimal performance and longevity, reducing downtime and project delays. Additionally, strict adherence to safety protocols is crucial to protect workers from potential hazards and ensure a safe working environment. Proper training and adherence to industry standards are essential for maintaining a high level of safety in road construction projects.

7. Advancing Technology: The Future of Asphalt Road Construction

The world of asphalt road construction machines is constantly evolving, with technological advancements driving efficiency and innovation. From automated asphalt pavers and rollers to GPS-guided milling machines, cutting-edge technologies are revolutionizing the industry. These advancements enhance precision, productivity, and safety, leading to improved road quality and reduced project timelines.

Conclusion

Asphalt road construction machines are the driving force behind modern road construction, shaping our transportation networks and connecting communities. Their intricate design and diverse applications make them essential tools in building and maintaining safe and durable asphalt pavements. As technology continues to advance, the future of asphalt road construction machines promises even greater efficiency, sustainability, and innovation, transforming the way we build and maintain our roads.

-

Are you seeking a reputable and dependable agency for construction workers in Singapore? We provide skilled and experienced construction workers for various projects. Click here to learn more about how we can help address your construction needs in Singapore.

-

In pursuit of a construction opportunity in London, consider exploring agency work in London construction. We offer access to numerous construction jobs throughout the city. Find out more about our agency’s offerings and the available construction positions in London.

-

Discover the step-by-step process of constructing asphalt roads by exploring our guide on asphalt road construction procedure. Gain insights into the materials, equipment, and techniques involved in building durable asphalt roads. Read more about the procedures and standards for constructing asphalt roads.

Maintenance and保养: Guidelines for maintaining asphalt road construction machines to ensure optimal performance and longevity, including routine inspections, lubrication, and parts replacement.

Asphalt road construction machines demand regular maintenance to ensure peak performance and extended service life. This comprehensive guide provides detailed instructions on maintaining these machines, encompassing routine inspections, lubrication, and parts replacement.

Routine Inspections:

-

Visual Examination:

-

Regularly inspect machines for any signs of damage, leaks, or unusual wear.

-

Examine tires for wear and tear; monitor tire pressure.

-

Functional Testing:

-

Test machine functions to ensure proper operation.

-

Check gauges, lights, and safety devices.

-

Lubrication:

-

Lubricate moving parts, bearings, and chains according to manufacturer’s recommendations.

-

Use high-quality lubricants to reduce friction and wear.

-

Parts Replacement:

-

Replace worn or damaged parts promptly.

- Keep a stock of commonly used parts to avoid project delays.

Maintenance Schedule:

- Daily Maintenance: Perform basic visual inspections and simple tasks.

- Weekly Maintenance: Conduct thorough inspections, lubricate moving parts, and replace minor parts.

- Monthly Maintenance: Schedule comprehensive maintenance, addressing more complex mechanical issues.

- Annual Maintenance: Perform major overhauls and service, including engine tune-ups and transmission checks.

Safety Precautions:

- Lockout/Tagout Procedures: Follow proper procedures when servicing or repairing machines.

- Wear Personal Protective Equipment (PPE): Use appropriate PPE, including gloves, safety glasses, and hard hats.

- Train Operators: Provide training on safe operation and maintenance procedures.

Key Takeaways:

- Regular maintenance extends the lifespan of asphalt road construction machines.

- Routine inspections identify potential issues early, preventing costly breakdowns.

- Proper lubrication reduces friction and wear, enhancing machine performance.

- Prompt parts replacement ensures optimal machine operation and project efficiency.

- Adhering to a maintenance schedule optimizes machine uptime and productivity.

- Safety precautions minimize risks and ensure a safe working environment.

Sources:

- Asphalt Pavement Maintenance Optimization

- Risk Management for Asphalt Road Construction and Maintenance Projects

Safety Precautions: Essential safety measures to be observed when working with asphalt road construction machines, including personal protective equipment, traffic control, and emergency procedures.

Working with asphalt road construction machines demands meticulous attention to safety protocols. These colossal machines, while engineering marvels, can pose significant risks if proper precautions aren’t taken. From personal protective equipment to traffic control measures, every aspect of the construction site must adhere to stringent safety guidelines.

Key Takeaways:

-

Protective Gear: Hard hats, safety glasses, steel-toed boots, high-visibility vests, and respirators are essential for safeguarding workers from flying debris, hazardous fumes, and extreme temperatures.

-

Traffic Control: Effective traffic management plans, including signs, barricades, and flaggers, help prevent accidents and ensure smooth traffic flow near construction zones.

-

Emergency Preparedness: Having a comprehensive emergency response plan in place is paramount. This includes designated assembly points, fire extinguishers, first aid kits, and trained personnel to respond swiftly to any unforeseen circumstances.

-

Machine Maintenance: Regular maintenance and inspections of asphalt road construction machines minimize the risk of breakdowns and accidents. Adhering to the manufacturer’s guidelines for maintenance is vital.

-

Training and Supervision: Ensuring that all personnel operating asphalt road construction machines receive adequate training and supervision is non-negotiable. This includes familiarization with the machine’s controls, safety features, and emergency procedures.

-

Communication and Coordination: Clear communication and coordination among workers, supervisors, and traffic controllers are crucial to prevent misunderstandings and accidents. Establishing hand signals and using radios or other communication devices facilitate seamless coordination.

Remember, safety is not just a procedure; it’s a mindset. By instilling a culture of safety consciousness among workers and strictly adhering to established protocols, asphalt road construction projects can be completed efficiently and without compromising the well-being of those involved.

Citations:

[1] Asphalt Safety Training Program: Texas Department of Insurance

[2] 11 Essential Road Construction Safety Tips | BigRentz

Common challenges and Troubleshooting: A discussion of common issues that may arise during asphalt road construction and troubleshooting tips for resolving them efficiently.

Greetings, fellow road construção enthusiasts! Welcome to an in-depth exploration of the intriguing challenges and troubleshooting techniques associated with asphalt road construction. As a seasoned professional, I’ve encountered countless scenarios where unforeseen obstacles threatened to derail our projects. But fear not, for we’ll delve into the depths of these trials and unveil practical strategies to overcome them.

Let’s kick off our journey with one of the most prevalent challenges: incorrect asphalt mix design. Picture this: you’ve meticulously laid the foundation, only to discover that the asphalt mix lacks cohesion or exhibits excessive cracking. The culprit? An imbalance in the asphalt cement, aggregate gradation, or compaction. To rectify this, we must ascertain the root cause through thorough testing and adjust the mix design accordingly.

Next up is the dreaded asphalt segregation. Imagine a scenario where the asphalt mixture separates into its various components, leading to unevenness and premature failure. The remedy lies in ensuring proper mixing and transportation techniques. Additionally, employing a paver equipped with an auger system can help maintain a homogeneous mix throughout the paving process.

Moving on, we encounter the pesky raveling and stripping. These conditions arise when the asphalt binder fails to adhere to the aggregate, resulting in loose stones and moisture damage. To counter this, we must select the appropriate asphalt binder based on traffic volume and climatic conditions. Furthermore, optimizing the compaction process and ensuring a clean aggregate surface are key preventive measures.

Now, let’s address the notorious rutting and shoving. Envision a scenario where heavy traffic causes permanent deformation, creating undesirable ridges and depressions. To combat this, we must employ asphalt mixes with adequate stability and shear resistance. Moreover, ensuring proper compaction and avoiding excessive traffic during the curing period are essential safeguards.

Lastly, we confront the ever-present cracking. From thermal cracking in cold climates to fatigue cracking under repeated traffic loads, cracks can compromise the integrity of our asphalt pavements. To mitigate these issues, selecting the appropriate asphalt binder and implementing proper joint design and construction techniques are crucial.

In summary, asphalt road construction is a multifaceted endeavor that demands vigilance and adaptability. By comprehending these common challenges and embracing the troubleshooting techniques outlined above, we can successfully navigate the complexities of this field and deliver enduring asphalt pavements that stand the test of time.

Key Takeaways:

- Incorrect asphalt mix design:

-

Ensure proper mix design through testing and adjustments.

-

Asphalt segregation:

-

Employ proper mixing, transportation, and paver techniques.

-

Raveling and stripping:

-

Select appropriate asphalt binder and optimize compaction.

-

Rutting and shoving:

-

Use stable asphalt mixes and avoid excessive traffic during curing.

-

Cracking:

- Choose suitable asphalt binder and implement proper joint design.

Sources:

- Asphalt Pavement Construction and Maintenance Guide

- Asphalt Road Construction Best Practices Guide

FAQ

Q1: What are the essential machines used in asphalt road construction?

A1: Asphalt pavers, rollers, milling machines, asphalt plants, and truck cranes are among the key machines used in asphalt road construction. These machines work in tandem to lay, compact, and maintain asphalt roads efficiently.

Q2: How do asphalt pavers contribute to road construction?

A2: Asphalt pavers are responsible for laying asphalt mix onto the road surface. They distribute the asphalt evenly and precisely, ensuring a smooth and level pavement. The pavers can be equipped with various features, such as grade control systems and automatic screeds, to achieve high-quality results.

Q3: What role do rollers play in asphalt road construction?

A3: Rollers are used to compact the asphalt mix after it has been laid. They help eliminate air voids and ensure proper bonding between the asphalt layers. Different types of rollers, such as vibratory rollers and tandem rollers, are employed depending on the project requirements and asphalt mix characteristics.

Q4: How are milling machines utilized in asphalt road construction?

A4: Milling machines are used to remove existing asphalt pavements for resurfacing or rehabilitation projects. They have rotating drums equipped with cutting teeth that mill the asphalt surface to a specific depth. Milling machines allow for precise removal of damaged or deteriorated asphalt layers, preparing the road surface for new asphalt placement.

Q5: What are the primary functions of asphalt plants in asphalt road construction?

A5: Asphalt plants are facilities designed to produce asphalt mix for road construction. They combine various materials, including aggregate, bitumen, and additives, to create asphalt concrete. Asphalt plants can vary in size and production capacity, with larger plants capable of producing hundreds of tons of asphalt per hour to meet project demands.

- Upgrade Your Table Setting: Best Salad Forks 2025 - June 26, 2025

- Sage Green Throw Pillows: Transform Your Home Decor - June 26, 2025

- Find the Perfect Sage Green Rug: A Buyer’s Guide - June 26, 2025